1410 WEST LARK INDUSTRIAL PARK | FENTON, MO 63026 | PH: 636-677-3364 | FAX: 636.305.1265

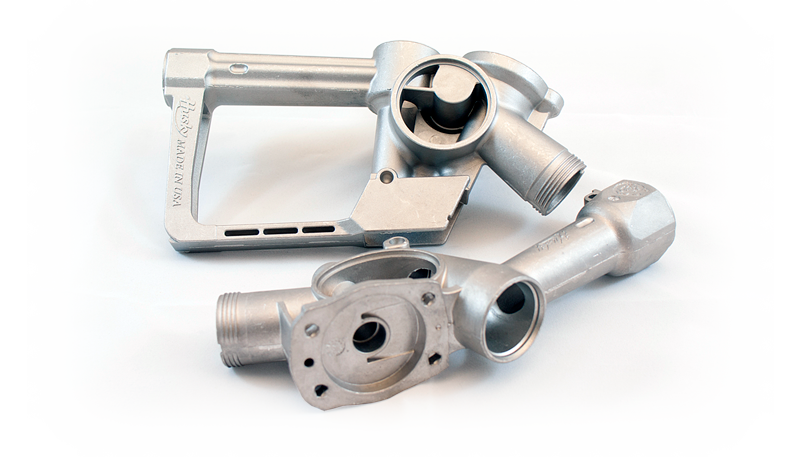

Aluminum Die Casting

PRODUCTION CASTINGS HAS BEEN PRODUCING ALUMINUM DIE CASTINGS & ZINC DIE CASTINGS, SINCE 1976.

We can offer many different die casting solutions because of our wide selection of die casting machines.

Aluminum die casting alloys are lightweight while possessing high dimensional stability for complex shapes and thin walls. Aluminum has good corrosion resistance and mechanical properties, high thermal and electrical conductivity, as well as strength at high temperatures.

Because of the superior mechanical properties, aluminum die castings are among the highest volume, mass produced items manufactured by the metalworking industry today.

Aluminum die castings are everywhere. They can be found in thousands of consumer, commercial and industrial products.

Aluminum die castings are important components of products like automobiles, computers, washers, dryers, refrigerators, furnaces and even toys. Some parts can be as simple as a faucet handle or as complex as transmission housing.

Production Castings is a proud American Manufacturer and we are a better value than the offshore competition.

THE DIE CASTING PROCESS

Die casting is a versatile, efficient and economical process for producing engineered metal parts.

Die casting offers a broader range of shapes and components than any other manufacturing technique.

The die casting process requires a steel mold. These reusable steel molds, called dies, can be designed to produce complex shapes with a high degree of accuracy and repeatability.

The dies are mounted into a machine that injects molten metal into the dies under high pressure. Once the molten metal has solidified, the die is opened and the casting is ejected from the mold. The die is then closed and the process starts over.

Aluminum Cold Chamber Die Casting Machine

ADVANTAGES OF ALUMINUM DIE CASTING

The die casting process provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical castings can be produced in a very short time.

Die castings have a long service life because they are durable, dimensionally stable, and heat resistant.

Die cast parts are stronger than plastic injection molded parts having the same dimensions. Die castings can be produced with thinner wall sections that are not possible with other casting methods.

Die castings can be smooth or textured and they are easily plated or painted with a minimum of surface preparation.

Die castings offer simplified assembly by providing integral fastening elements such as bosses and studs. Holes can be cored and made to tap drill sizes or external threads can be cast.

Zinc Hot Chamber Die Casting Machine